EQUIPMENT

CUSTOM EQUIPMENT TO POWER YOUR PROTEIN PROCESSING LINES

We combine our experience and standard designs with your layout and goals to design, fabricate, and install stainless steel equipment and systems on your schedule.

FOOD-GRADE EQUIPMENT CATEGORIES

Our core stainless steel equipment falls into the following categories. Contact us for custom equipment and systems.

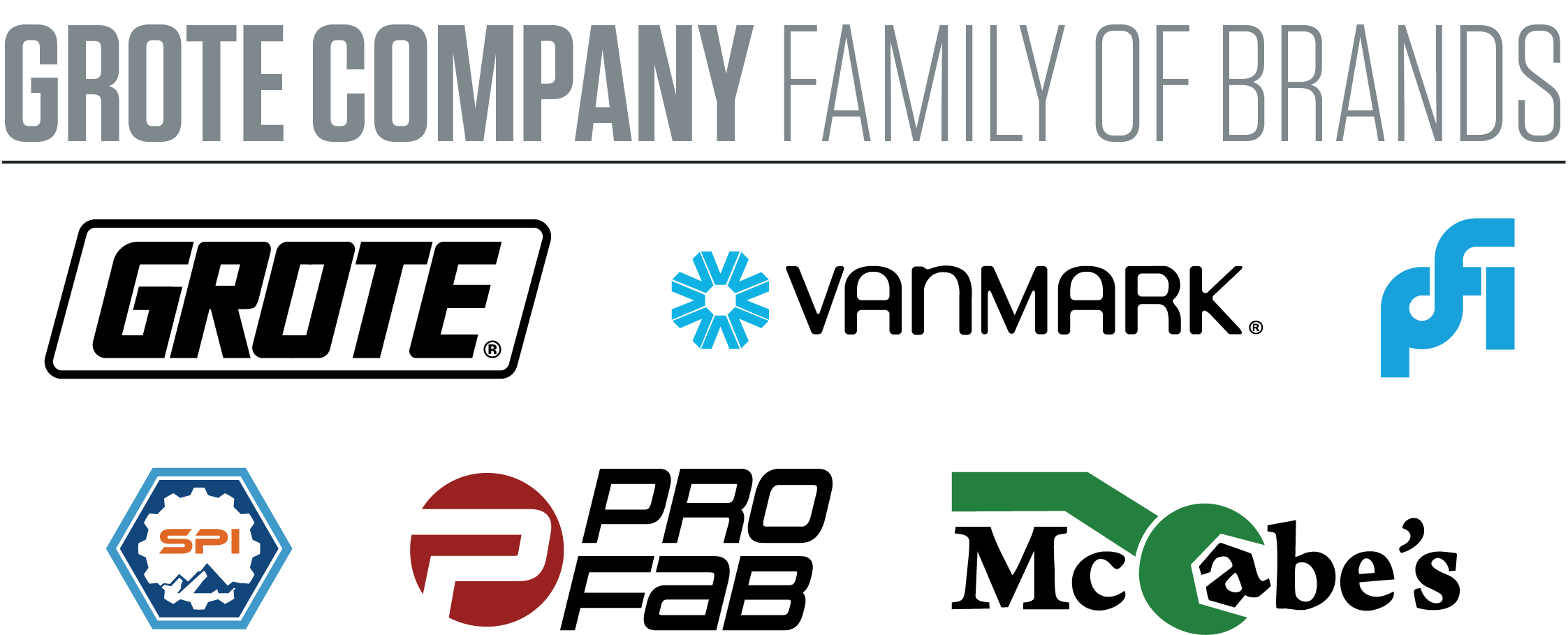

CONVEYORS

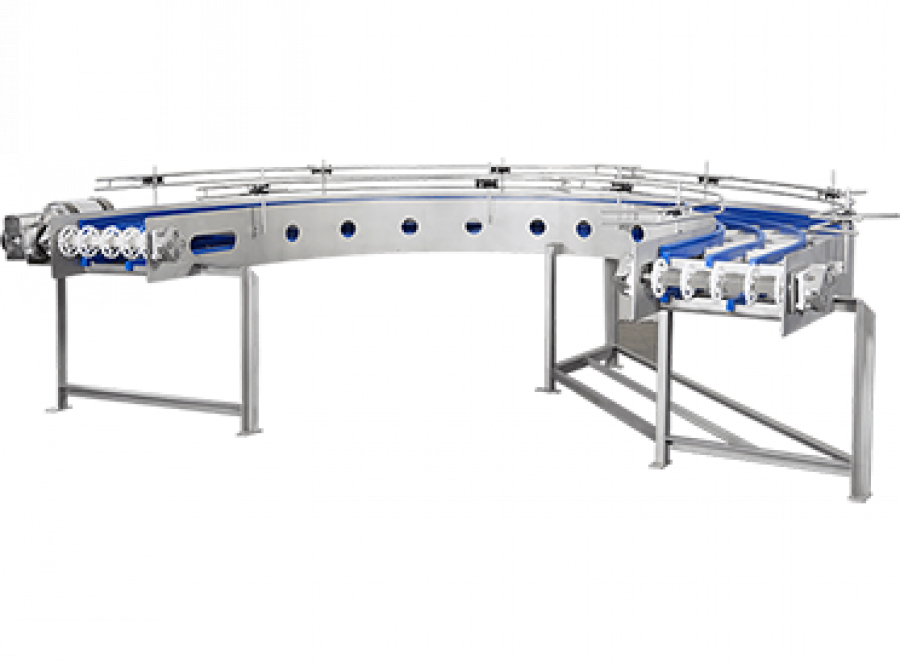

PLATFORMS

HYGIENE & STANDS

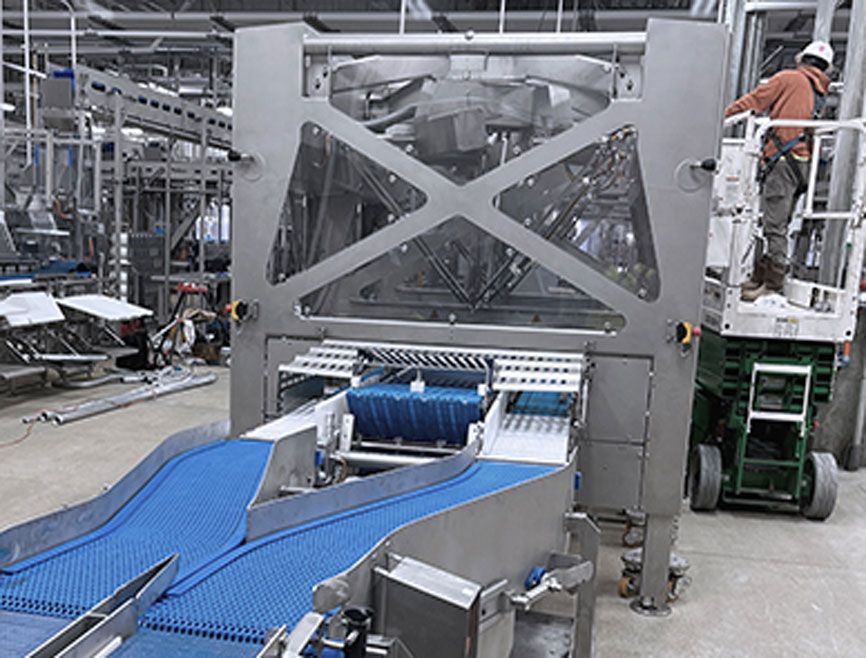

FULL SYSTEM CAPABILITIES

Trust ProFab to supply systems for your key processes. We use our industry expertise, fast fabrication, process piping, and holistic millwright and mechanical services to supply the following meat and poultry processing systems:

- Marination Piping

- Deboning Cone Lines

- Trussing

- Trim Lines

- Packing & Cartoning

- And more

MEAT & POULTRY PROCESSING CUSTOMERS

WHY PROFAB

We know the industry’s demands. Production time is measured in minutes and hours, not days and weeks. We respond quickly to meet your deadlines and use our experience and pool of resources to complete projects.

EXPLORE INDUSTRIAL SERVICES

We respond quickly with these services to support your food processing plants.